Add to Cart

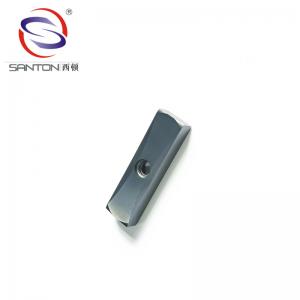

For Nodular Cast Iron Creep Grinding Cast Iron Good Resistance Carbide Milling Inserts

Grade Information:

| Santon Grade | Performance typical value | Characteristics & Applications | ISO Code | Equivalent Grades | |||

| Density (g/cm3) | TRS (N/mm2) | Hardness (HRA) | |||||

| SK233-1 | 14.3-14.55 | 2800 | 91.5-92.5 | Extra fine substrate, high strength,good resistance to impact,vibration and wear,better red hardness,roughing and heavy milling for gray cast iron,nodular cast iron,creep grinding cast iron, non-ferrous metal,roughing for non-metallic materials, particularly for dry cutting applications. | K | K30 | |

Product Description:

The vertical blade realizes the function of "milling belt grinding". Processing shape: inner circle outer circle, plane. Processing objects: steam, diesel engine cylinder block cylinder head, steam turbine blades, large bearing inside and outside surface processing, crankshaft processing. Processing materials are generally: steel, cast steel, cast iron (ductile iron, gray cast iron, vermicular cast iron), high temperature alloy, titanium alloy, aluminum alloy and so on.

Certifications:

Company Information:

We have perfect carbide material analysis process and channels and strong ability of independent research and development of the material, the material (brand) is in the leading level in the trade, and made with special blade material (brand) is the most complete in the peer enterprises at home and abroad, material instead of foreign brands (brand) one of the most hard alloy production enterprises.

Company research and development, production, marketing positioning in high-end, replace imports "in the" vertical blade series, in the engine cylinder block cylinder head milling, large ships gear milling, screw milling, high-speed rail processing and restoration, large-scale hydraulic power station steam turbine rotor milling, the crankshaft milling, aluminum and titanium alloy milling industries such as aerospace industry has a certain popularity and occupy a certain market share.

FAQ:

Q. Are you a manufacturer or a trading company?

A. We are a professional manufacturer with 10 years of experience of producing and selling carbiede inserts.

Q. What is your main products?

A. Our main products includes cemented carbide plates, strips, blanks, saw tips, geological and mining bits, brazed tips, indexable carbide inserts, wear parts,snow plow inserts, tungsten carbide pins, etc.

Q. what's the payment term?

A. We accept Western union, Onetouch, T/T, and L/C. 30% T/T deposit and 70% balance before shipment, or against copy of BL, or L/C at sight.

Q. What about your delivery time?

A. Usually it will take about 25 - 30 days for production.But for new molds, the lead time may need 10days more to open molds. If you need the goods urgently, we could try to push for and shorten the delivery time.

Q. What is your minimum order quantity(MOQ)?

A. No limit for MOQ. For non-standard products, mold fee need to be paid, but can be refunded later.

Q. What is your warranty?

A. We extend a 100% satisfaction guarantee on all items. if you’re not completely satisfied with our products ,we’ll replace them or refund the fee